Application Case of Silicon Carbide Crystal Growth Furnace in the Semiconductor Industry

2024-09-12

2024-09-12

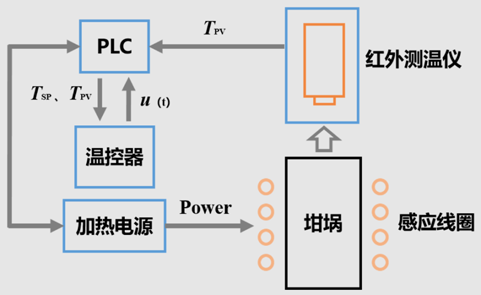

Physical Vapor Transport (PVT) is one of the mainstream methods for preparing silicon carbide (SiC) crystals. In PVT-based SiC single crystal growth, temperatures can reach up to 2300°C, requiring strict control of the temperature gradient during the process. The temperature control system employs a closed-loop design, consisting of an infrared pyrometer, a temperature controller, a heating power supply, and a heater (induction coil).

System Block Diagram:

Yudian AI Series Intelligent Controllers

1.AI-8x9 Series

2.AI-MODBUS-TCP1-24VDC

These controllers have been successfully implemented in silicon carbide (SiC) crystal growth furnaces at a leading domestic semiconductor equipment manufacturer. The system achieves precise temperature control, with the instruments supporting multiple I/O specifications, adjustable control cycles, and alarm functions. Communication interfaces include RS485 and RS232, and compatibility with external TCP modules enables seamless MODBUS-TCP communication.

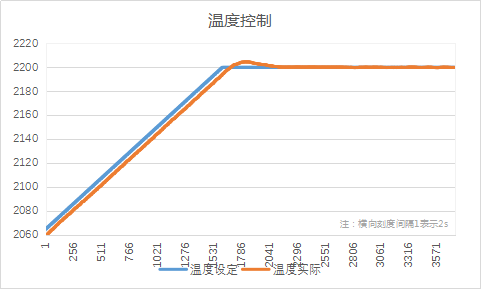

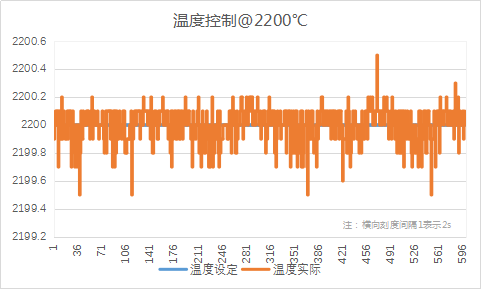

Temperature Control Performance:

Temperature Control Performance: Temperature fluctuation ≤±0.5°C at 2200°C, with overshoot and settling time metrics matching the performance of competing UK products. Validated by end customers, it serves as a direct replacement for imported counterparts, successfully achieving domestic substitution.

TOP